You’ve Heard Of Coal. Ever Hear Of Slag?

Globally coal is continuing to serve the modern and developing world’s energy interests. Any energy expert will tell you the power and influence of Coal on the power sector is undeniable. Coal is cheap, abundant and available to developing countries that intend to utilize it. Coal will remain popular in coal dependent Asian countries like China and India; experts predict coal will remain as the dominant fuel source for the next fifty years plus.

As time marches forward and more and more higher quality coal is mined and consumed, this leaves a growing problem. There becomes more and more low quality coal left over that must be consumed. As more power plants are forced into using lower quality, lower BTU coal and higher ash coal types, they must contend with numerous challenges. Poorer quality coal types tend to be more difficult to burn and tend to negatively impact on boilers performance. It also should be noted that boilers burning lower grade coals are being kept running at higher operating load for much longer periods of time to make up for the lower heat values of the lower BTU coal burned.

Due to the deteriorating quality in available coal, boiler operations have become more challenged. Poorer quality coals have caused many boilers to experience increasing slag deposits on the interior furnace walls, air preheater and super heater sections of their boilers. When a boiler has severe slagging in the boiler combustion chamber it forces the boiler to be shutdown for mechanical cleaning. All unscheduled or unnecessary shutdowns cost the boiler operator a lot of money. Severe slagging causes many different operational problems such as production delays and production losses, sometimes if the boiler is producing power there are other economic penalties. Unscheduled shutdowns due to slagging costs boiler operators billions of dollars per year in lost productivity.

What is slag and what causes slagging? Coal contains carbon, hydrogen and oxygen – all of these are combustible, however, there are numerous inorganic impurities that are not combustible and contribute to slagging. The inorganic parts affect ash fusion temperatures. A particular coal type’s ash might be known for its tendency to slag and foul is related to the chemistry of the ash and ash fusion temperatures. Ash fusion temperatures relate directly to the propensity for slag formation in the boiler. When slagging deposits form on the boiler’s fireside surfaces and continue to collect the slag density also increases with time creating a deposit that is very hard and difficult to remove with traditional soot blowing techniques. When a boilers soot blowers cannot remove the ash build up from the upper recesses of a boiler in a timely manner, slag deposits can continue to grow, harden, and form very large and dangerous deposits.

Slagging usually is occurring in the convective areas of the boiler where ash collects on the boiler tubes and internal surfaces inside the furnace, where it crystallizes and hardens. The slag than acts as a heat refractory, insulating the boiler rather than convicting the heat to the water inside the boiler tubes.

The continual ash deposition on the furnace walls is what causes slagging and it occurs in the high temperature areas of furnaces directly exposed to flame radiation. In other areas these deposits are called fouling when they’re in other regions such as on tubes in the convection section of the boiler.

Why is slagging so bad? When large slag deposits form they can unexpectedly fall. Falling slag can puncture boiler tubes; damage the floor of the lower furnace forcing an unscheduled shutdown and lost production. When a large slag formation falls it will often damage the system.

In order to avoid severe slagging and unscheduled shutdowns, boiler operators are offered a fireside chemical treatment, CC-88.

CC-88 is a fireside chemical treatment. CC-88 is added to the coal on the coal feed conveyor belt and fed into the furnace along with the coal. CC-88 has proved its ability to significantly reduce slagging, fouling and plugging of boilers burning coal.

How does CC-88 work to reduce slagging? CC-88 plays a significant role in preventing the ash from sintering and fusing. Fusing and sintering describes the physical and chemical bonding of deposited slag particles. As sintering progresses, it results in increasing strength of deposits. Therefore preventing the ash from sintering and hardening is the objective of CC-88. CC-88 has a unique catalytic ability to generate oxygen, thereby enabling more complete combustion of more of the carbon contained in each tonnes of coal.

CC-88 promotes a slow burning by softening the hard carbon deposits and cracking slag formation, penetrating their surfaces and further cracking, which increases the slag porosity, and promotes cracking at the surface of the ash, thereby making the slag easier to remove with soot blowers.

CC-88 also work to decrease the melting point and friability of deposits formed from the ash constituents in the coal during combustion process. By changing the slag’s porosity makes the slag easier to remove during normal soot blowing and out-of-service cleaning.

After use of CC-88 combustion catalyst, boilers slagging, fouling and plugging problem are reduced dramatically. Boiler Temperature profiles in the furnace and exit flue gases are consistently lower when compared to operating the boiler with heavy slag.

Combustion catalysts improve boiler efficiency by extracting more heat energy from the fuel and by reducing heat losses when operating at minimum excess air. In addition, an effective combustion catalyst may reduce the level of smoke and solid combustibles and help a plant attain emissions compliance requirements that are not always achieved with the existing pollution control equipment. Combustion catalysts promote the combustion process by lowering the ignition temperature of the fuel, allowing for a longer burn time, and increasing the rate of combustion.

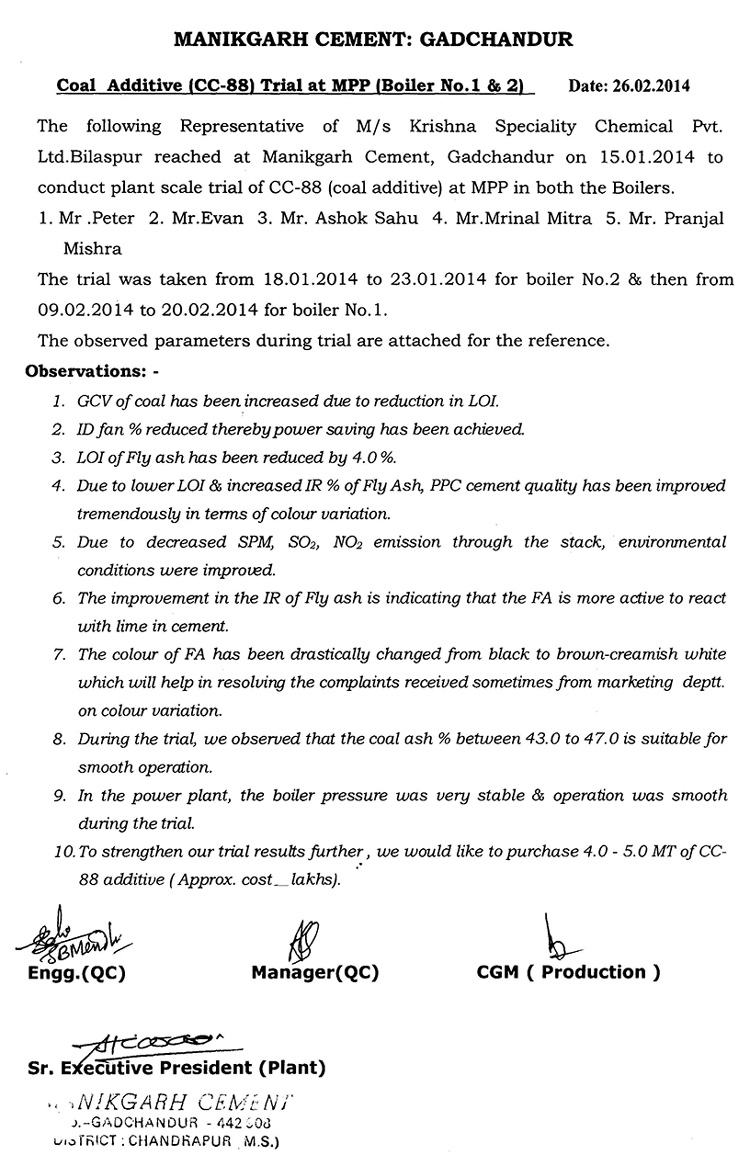

In February of 2014, Asia Coal Catalyst Company conducted successful trials at Manikgarh Cement located in Chandrapur, Maharashtra, India http://www.manikgarhcement.com

In February of 2014, Asia Coal Catalyst Company conducted successful trials at Manikgarh Cement located in Chandrapur, Maharashtra, India http://www.manikgarhcement.com